Porous control valve

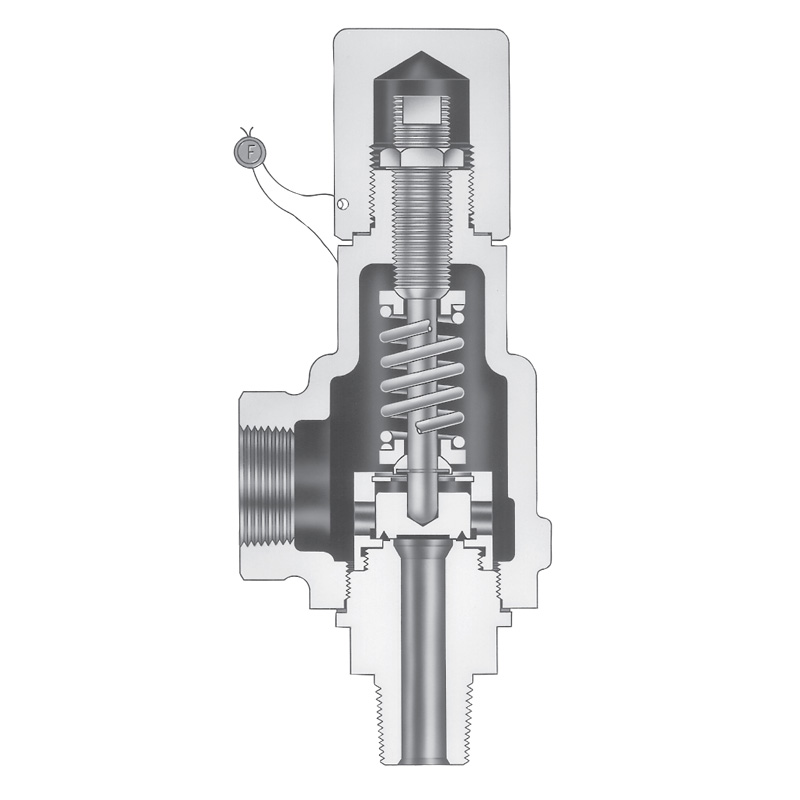

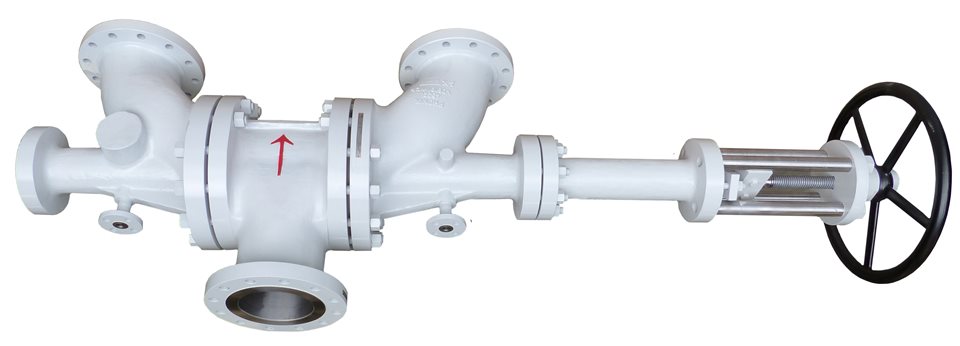

The multi hole low noise pneumatic control valve adopts sleeve guide and pressure balance valve core. It is a high performance control valve with good dynamic stability and suitable for harsh working conditions. Because the working condition pressure difference is big, the medium flow rate is fast, the valve internals will produce serious erosion damage and noise at the same time. Therefore, we changed the window type standard sleeve into a porous sleeve. For the general flow direction of liquid is from high to low of the valve, the medium is collided in the sleeve by porous throttling, and the internal energy consumption can reduce the flow rate. For the gas medium, the low inlet and high outlet are generally adopted. After the throttling of the porous sleeve, the gas medium has a volume expansion behind the valve seat, thus reducing the pressure of the medium and reducing the flow rate.

Parameter Description:

Trim features: sleeve guided

Balanced internals construction

Balanced seal ring structure (normal temperature)

Metal seal ring structure (high temperature)

Body type: straight through / angle

Cover type: standard heat dissipation type

Fast flow characteristic: equal open percentage

Caliber range: dn40-400 (1.5 "- 16")

Pressure rating: pn1.6, 4.0, 6.3MPa (ansi150, 300, 600Lb)

Leakage class: asmeb16.104 V (standard metal seat)

Asmeb16.104 Ⅵ (cut off soft seat)

Pipe connection: flange butt welding

Applicable temperature range: - 30 ° - 260 ° (balanced seal ring structure) - 196 ° - 550 ° (metal seal ring structure)

Actuator type: pneumatic diaphragm actuator

Pneumatic piston actuator

Electric actuator

PRODUCT

Contact Us

Contact: Dandy

Email: australiadaume@outlook.com

Add: 54 Orchard St, Glen Waverley VIC 3150