Globe Valves

Daume Valves Division offers a wide range of globe valves in a variety of construction materials, showcasing a variety of versatility and adjustment to suit a diverse set of specifications. Globe valves are designed to stop, start, and regulate flow within a pipeline, by means of throttling and isolation. These types of valves can be used in application with marine ballast systems, as well as heating and air conditioning, water distribution and/or treatment, and much more.

Our globe valves feature the three typical body designs: Tee, Angle, and Wye pattern, and we also supply electric, hydraulic, and more, types of valve actuators to suit every industrial requirement.

GLOBE VALVES: PURPOSE & FUNCTIONALITY

Features and Benefits

Easy maintenance and repair

Good shutoff capability

Shorter stem travel

Available in a variety of patterns

Good throttling capability

It can be used as a stop check valve

Globe Valve Applicaitons

Cooling water systems

Fuel oil systems

Boiler vents and drains

Turbine seals and drains

TYPES OF GLOBE VALVES

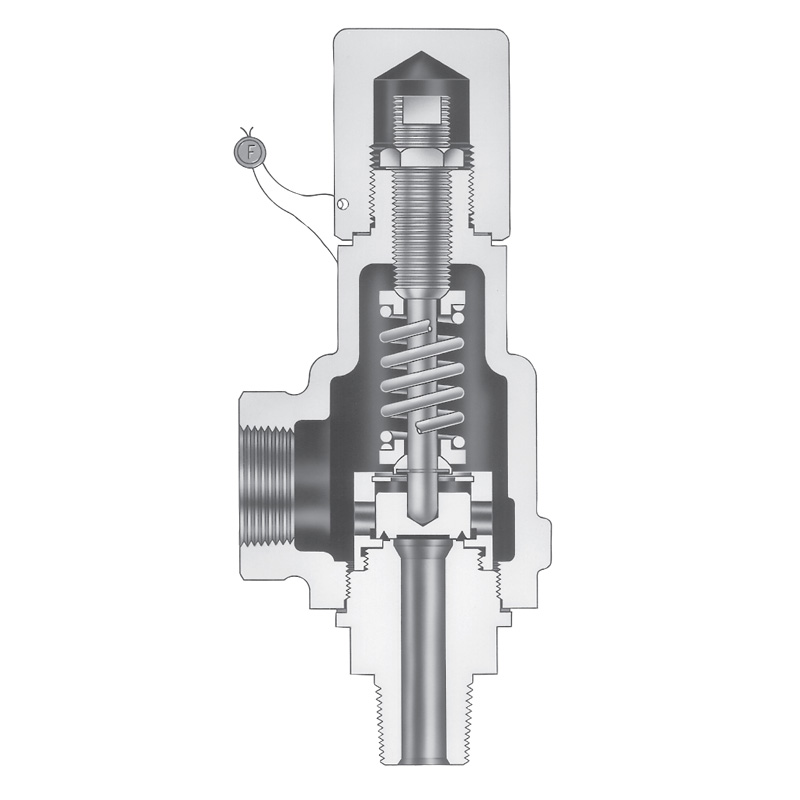

Standard Pattern Globe Valve

The most common of the three, it's used in throttling services such as around a control valve by allowing the stem and disk to move at an angle towards the fluid’s direction.

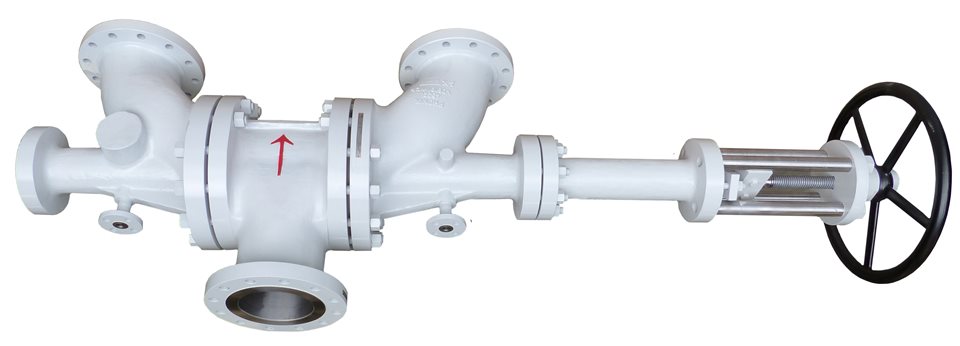

Angle Pattern Globe Valve

An angle pattern globe valve features a 90-degree angle at the ends. This unique design means that angle pattern globe valves are functional in applications that have pulsating flow. It’s highly advantageous when mounting near a pipe bend; the angle design reduces the flow resistance and reduces the number of pipe joints and elbows.

Oblique Pattern Globe Valve

In an oblique pattern globe valve, the seat and stem measure at approximately 45 degrees. Giving a more direct path at full opening and also offering the least resistance to flow. They are a suitable alternative for a high-pressure drop application.

ELECTRIC GLOBE VALVE

An electric globe valve is a valve that features an electric actuator driving the stem up and down. It changes the distance between the disc and the seat to achieve opening and closing and is mainly used in cut-off applications. An electric cut-off valve is primarily used to gain precise control in demanding hot and cold water applications, including steam and compressed air applications.

Beneftis

Simple structure and lightweight design.

Easy to operate with a quick response to open and close.

Convenient maintenance, disassembly, and replacement if needed.

Wide range of applications.

Small fluid resistance.

Tight and reliable design to ensure proper sealing.

Resilient performance from arduous media.

Ensures it’s always operational and efficient.

Electric Globe Valve Applications

Curtiss Wright Valve Division offers a selection of globe valves that suit various applications. Here are some of the more common placements for electric actuated globe valves.

Large mixing and diverting circuits

Air handling units.

Chillers.

District heating appliances

Constant and variable flow circuits

Cooling water systems.

Fuel oil systems.

Feedwater or chemical feed systems.

Marine environments.

HYDRAULIC GLOBE VALVE

A hydraulic globe valve uses hydraulic fluid to power the stem and allows it to move up and down to control the flow rate. They can be used to completely shut off the flow, redirect pressurized fluid, or control the level of flow.

Hydraulic globe valves are quick to respond but are not ideal for environments under high pressures, as gas is compressible. Hydraulic globe valves are designed to be cost-effective in a compact assembly, providing a highly accurate flow-versus-stroke characteristic.

Beneftis:

Rugged and suited to high-force applications.

They can produce forces 25 times that of a pneumatic valve.

Operate pressures up to 4,000 psi.

Minimal loss of power when pumps and motors are spaced apart.

Hold torque constant without a pump constantly supplying fluid.

Easy to maintain.

Accurate and efficient.

Hydraulic globe valves Applicaitons

Hydraulic globe valves suited a range of applications where high force and torque are required, including:

Hydraulic fluid power systems

Construction machines

Stationary systems - balers/presses

PRODUCT

Contact Us

Contact: Dandy

Email: australiadaume@outlook.com

Add: 54 Orchard St, Glen Waverley VIC 3150