Butterfly Valves

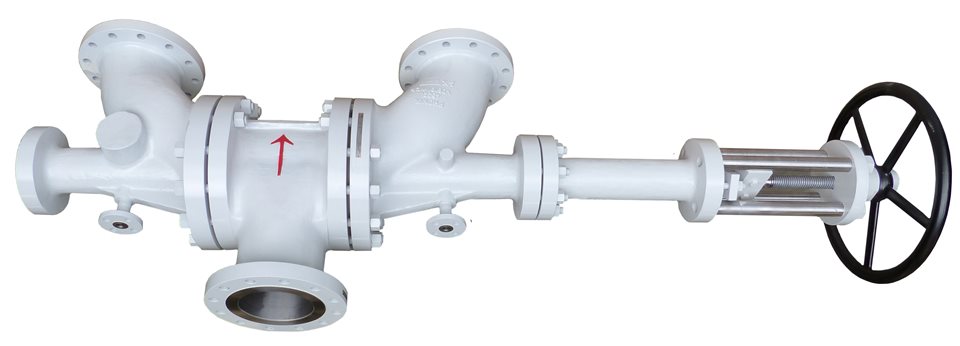

Daume Butterfly Valves isolate or regulate the flow of fluid by using a closing mechanism with a rotating disc. These valves allow for a cost-effective and lightweight solution.

Among the valves on offer are Double Block & Bleed, Triple Offset Segment Values that provide absolute shut-off and PTFE Sealed Fire-safe Valves. These systems, as well as an absolute commitment to outstanding quality and reliability, have assisted our successes in supplying engineering projects globally.

We offer high-performance butterfly valves (HPBV) with a variety of custom features:

Soft seating or ebonite-lined designs in sizes 2" (50 mm) to 138" (3400 mm)

Metal-seated

Zero leakage

Bi-direction triple offset segment valves (TOSV) in sizes 2" (50 mm) to 84" (2100 mm) in pressure classes up to ANSI 1500# with fully rated trims.

Our range also includes cryogenic, double block & bleed and our unique triple offset gate valve series

Butterly Valves:The Basics:Operation & Functionality

Butterfly Valves isolate or regulate the flow of fluid by using a closing mechanism with a rotating disc. Curtiss-Wright Valve Group offers butterfly valves from its Solent & Pratt brand.

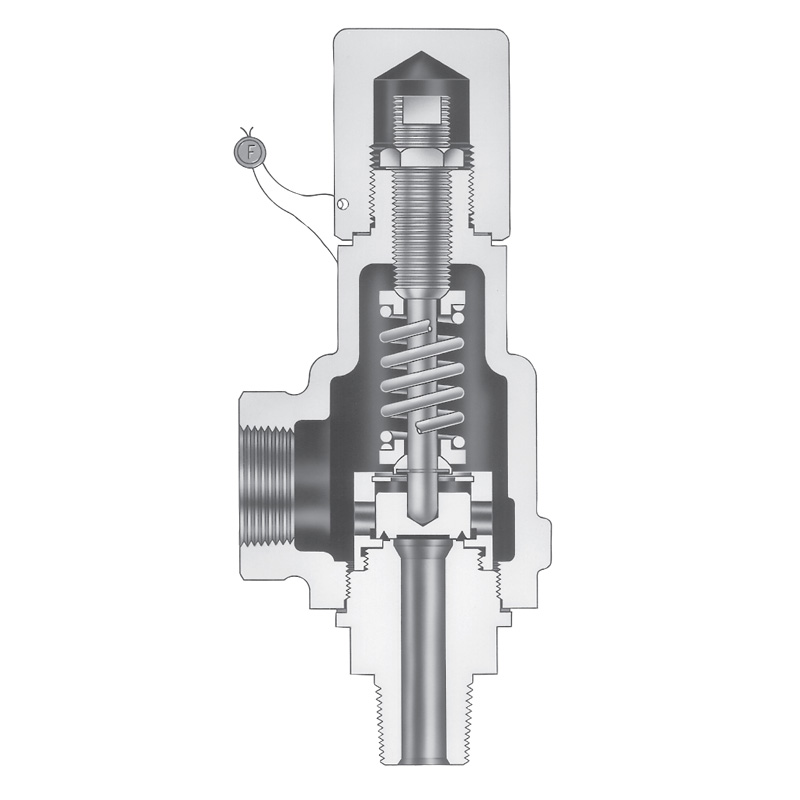

The operation of a butterfly valve is very similar to a ball valve. The ‘butterfly’ is a metal disk positioned in the center of the pipe, mounted onto a rod that passes through the disk to an actuator outside the valve. However, unlike a ball valve, the disk is always present within the flow, resulting in a slight drop pressure drop even when fully open; this is offset by lower costs and smaller size used in larger diameter pipes.

Turning the disk once the valve is closed blocks off the passageway but doesn't create as complete a seal as some alternatives, making options such as globe valve's a better fit for controlling gas flows. A full open valve allows the disk to rotate at a quarter turn giving unrestricted passage for the fluid.

Benefits:

Easy to open

Fast operation

Cost-effective solution

Lightweight design

Minimal pressure loss

Available in substantial sizes

Built for remote operation

Operated by handles, gears, or automatic actuators

Types of Butterfly Valves

At Curtiss Wright, we hold a variety of butterfly valves for many applications. They can come in diverse designs, each of which serves specific environments and pressure ranges. Butterfly valves are categorized based on their disc closure design, connection design, and actuation method.

There are three common types of butterfly valves, zero offset, double offset, and triple offset.

Zero-Offset Butterfly Valve

A zero offset butterfly valve is known for its concentric design and is often called resilient seated or rubber seated butterfly valves. They rely on the flexibility of rubber to create a seal. The valves have the lowest pressure rating and include a stem and disk centered in the seat and body of the valve. The fully protected seat is used to reduce the risk of any solids damaging the seating surface.

Zero-Offset Butterfly Valve Applications

A zero-offset butterfly valve is commonly used in applications such as handling:

Chemicals

Coatings

Abrasive

Food

Double-Offset Butterfly Valves

Used mainly for their shut-off and throttle control, high-performance double offset butterfly valves are designed to handle anything from general applications to corrosive liquids and gases. A double offset is used for higher pressures than the zero offset valves.

Valve Design

The valve has two stems offset from the center, creating a cam action when in use. One is offset from the centerline of the disk seat and body seal. The seat is lifted out of the seal, reducing friction resulting in less wear. The other is offset from the centerline of the bore.

Double-Offset Butterfly Valve Applications

A double offset butterfly valve is commonly used in:

Power generation

Chemical

Oil

Gas

Wastewater treatment

Shipbuilding

Triple Offste Butterfly Valves

Similar to the positioning of a double offset valve, the triple butterfly valve also has a third offset due to the seating surface’s positioning. Using this method allows the disc to seal against the seat without causing any friction.

The uniform sealing allows for a tight shutoff in a metal seat design and is famous for its low cost and low torque requirements.

Triple-Offset Butterfly Valve Applications

A triple offset butterfly valve is commonly used for:

High-pressure steam

Superheated steam

High-temperature gases and oils

PRODUCT

Contact Us

Contact: Dandy

Email: australiadaume@outlook.com

Add: 54 Orchard St, Glen Waverley VIC 3150