Gate Valves

Gate Valves: Purpose and Functionality

Gate valves are useful for fully open and fully closed service functions. Ideal for installation in pipelines as isolation components, the valve opens when lifting a gate out of the pathway of the fluid and closes when the gate returns to its position. However, they are not an appropriate component for controlling or regulating flow in valves.

Compact in design, gate valves require little space along the pipe axis and don’t restrict the flow when the gate is opened fully. They are also known as multi-turn valves and operate either clockwise to close or clockwise to open the rotating motion of the threaded stem.

BENEFITS:

Compact design

Lower cost point than ball valves

Available in many sizes, materials, temperature and pressure ratings, and gate and bonnet designs

Little resistance to flow

Gate Valve Application

Suitable for above-ground and underground installation, gate valves are useful in a wide variety of applications. Choosing the correct valve dependent on its application is vital, so there are no high replacement costs. Gate valves are often used when minimum pressure loss and a free bore are needed.

They’re suitable for the following disciplines:

Agricultural

General industrial

Steam

HVAC

Boilerhouse

Water treatment and distribution (WRAS)

Compressed air and oil

Marine

Type of Gate Valves

Gate valves have different kinds of characteristics that are useful for various applications, but the two main types are parallel and wedge-shaped.

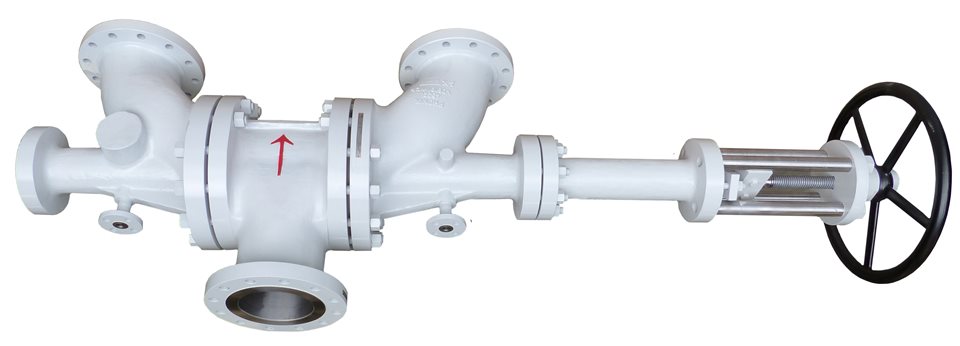

Parallel Gate Valves

Compact in its structure, with reliable closing and sealing performance, a parallel gate valve uses a flat gate between two parallel seats. Mainly used in the chemical, petroleum and natural gas field, it’s the ideal valve to provide isolation when closed.

Wedge-shaped Gate Valves

Wedge-shaped gate valves feature a disc that is in the shape of a wedge that seats between two inclined seats. Used in high flow or aggressive applications, it minimizes the vibration and chatter of the valve.

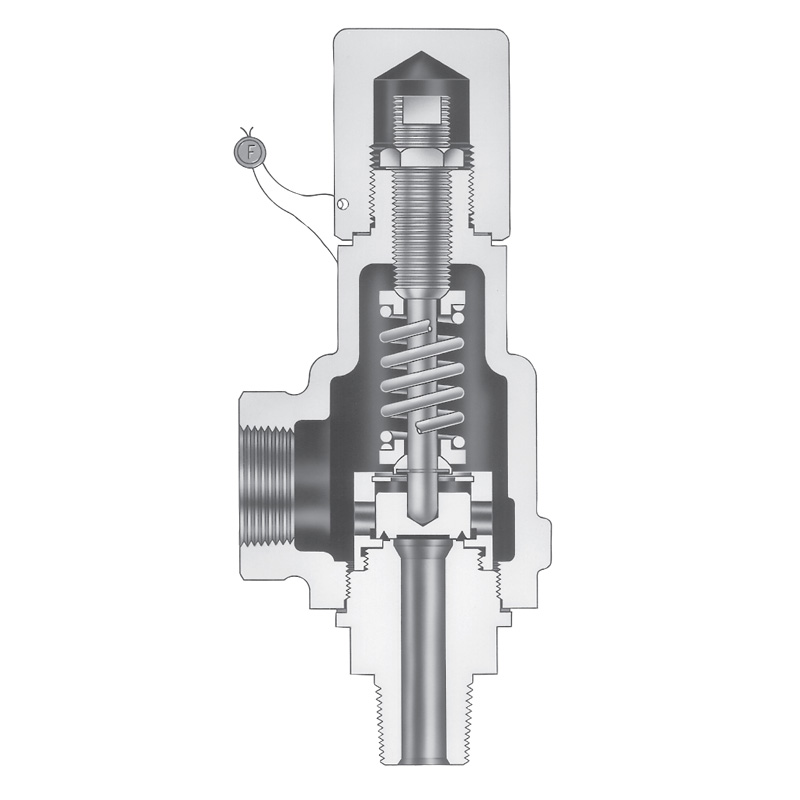

Rising Stem & Non-rising Stem Gate Valves

Made from a range of materials, their characterization can be seen by their rising or non-rising stem. A rising stem gate valve is only useful for above-ground installation. The stem fixes to the gate, and as it rises and lowers during operation, it indicates the valve position and the possibility to grease the stem. Suitable for both above-ground and underground installations, non-rising stems are embedded onto the gate, rotating with the wedge rising and lowering inside the valve. It’s ideal for a valve with limited space as they are more compact in design.

Rising stem Gate Advantages

Easy to open and close.

Small fluid resistance.

Medium flow is not restricted.

Easy to spot valve opening position by looking at the amount of stem that is exposed.

Types of Gate Valve Material

Gate valves come in a variety of different materials depending on the environment and application used. You can choose from the following materials:

Brass

Bronze

Cast Iron

Ductile iron

Stainless steel

Duplex

Carbon steel

Exotic alloys

Wedge Gate Valve Advantages

Flow resistance is small.

Media can flow in any direction on both sides of the wedge gate valve.

Easy to install.

Face to face dimension of a wedge gate valve is small.

Compact structure.

Long service life.

Sealing surface made of stainless steel and hard alloy results in a rigid design.

Suitable for a wide range of applications.

Wedge Gate Valve Disadvantages

Maintenance is difficult.

The type of sealing surfaces can quickly cause erosion and scratches.

Large in size.

It takes a long time to open and close.

A wedge gate valve’s structure is more complicated.

PRODUCT

Contact Us

Contact: Dandy

Email: australiadaume@outlook.com

Add: 54 Orchard St, Glen Waverley VIC 3150