Pressure relief Valves

Curtiss Wright selection of Pressure Relief Valves comes from its outstanding product brand Daume. We endeavor to support the whole life cycle of a facility and continuously provide custom products and technologies. Boasting a reputation for producing high quality, durable products, our collection of Pressure Relief Valves is guaranteed to provide effective and reliable pressure relief.

While some basic components and activations in relieving pressure may differ between the specific types of relief valves, each aims to be 100% effective in keeping your equipment running safely. Our current range includes numerous valve types, from flanged to spring-loaded, threaded to wireless, pilot operated, and much more.

Air Pressure Relief Valves: Purpose & Functionality

A pressure relief valve is a type of safety valve designed to control the pressure in a vessel. It protects the system and keeps the people operating the device safely in an overpressure event or equipment failure.

How does a pressure relief valve work?

A pressure relief valve is designed to withstand a maximum allowable working pressure (MAWP). Once an overpressure event occurs in the system, the pressure relief valve detects pressure beyond its design's specified capability. The pressure relief valve would then discharge the pressurized fluid or gas to flow from an auxiliary passage out of the system.

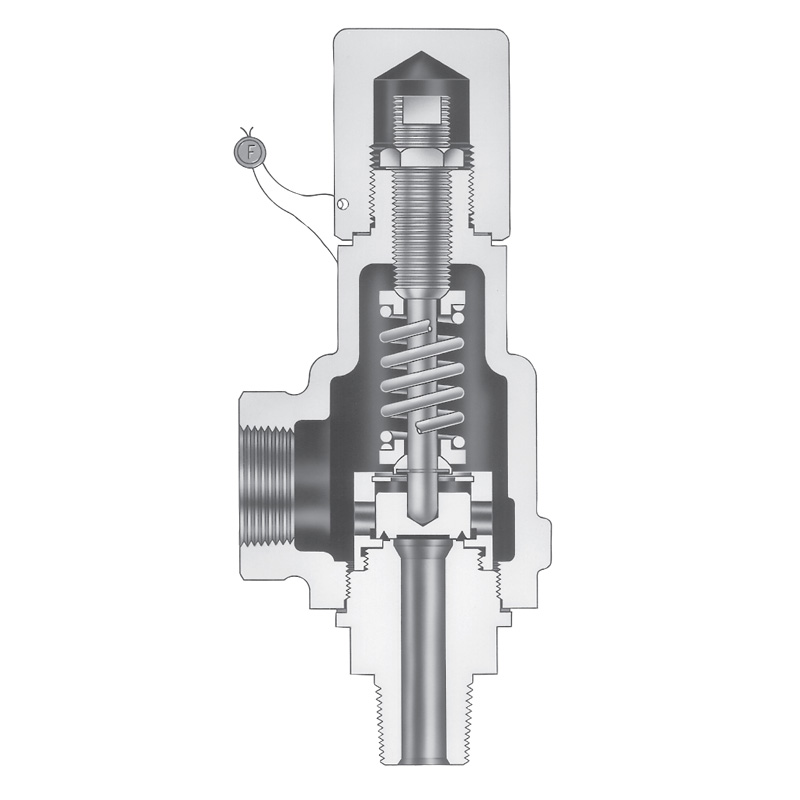

Below is an example of one of our pilot operated pressure relief valves in action; the cutaway demonstrates when high pressure is released from the system.

Pressure Relief Valve Applications

Air pressure relief valves can be applied to a variety of environments and equipment. Pressure relief valves are a safety valve used to keep equipment and the operators safe too. They're instrumental in applications where proper pressure levels are vital for correct and safe operation. Such as oil and gas, power generation like central heating systems, and multi-phase applications in refining and chemical processing.

Types of PRVS

At Curtiss-Wright, we provide a range of different pressure relief valves based on two primary operations – spring-loaded and pilot operated. Spring-loaded valves can either be conventional spring-loaded or balanced spring-loaded.

Spring-loaded PRVs

BENEFITS:

Operate at higher set pressures than pilot-operated relief valves

Extensive range of chemical compatibility

Operate at high temperatures

PILOT-OPERATED PRESSURE RELIEF VALVES

The valves allow media to flow from an auxiliary passage and out of the system once absolute pressure is reached, whether it is a maximum or minimum level.

When the pressure is below the maximum amount, the pressure differential is slightly positive on the piston's dome size, which keeps the main valve in the closed position. When system pressure rises and reaches the set point, the pilot will cut off flow to the dome, causing depressurization in the piston's dome side. The pressure differential has reversed, and the piston will rise, opening the main valve, relieving pressure.

When the process pressure decreases to a specific pressure, the pilot closes, the dome is repressurized, and the main valve closes. The main difference between spring-loaded PRVs and pilot-operated is that a pilot-operated safety valve uses pressure to keep the valve closed.

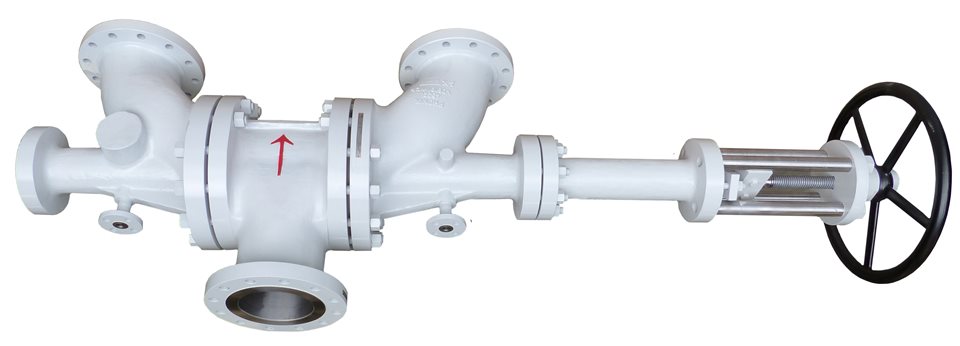

Pilot-operated relief valves are controlled by hand and are typically opened often through a wheel or similar component. The user opens the valve when the gauge signifies that the system pressure is at an unsafe level; once the valve has opened and the pressure has been released, the operator can shut it by hand again.

Pilot Operated Valve Advantages:

Modulating control PORVs minimize the release of media

Increasing pressure helps to maintain the pilot's seal. Once the setpoint has been reached, the valve opens. This reduces leakage and fugitive emissions.

Smaller design than spring-loaded valves and larger pipe sizes

Operate at pressures very close to the setpoint

PORVs are unaffected by back pressure

PORVs with remote sensing options are cost-effective solutions for PRV installations experiencing inlet pressure loss

More options for control

Can be used in engines

Seals more tightly as the system pressure approaches

Pilot Operated Valve Disadvantages

More complex

More expensive at smaller sizes

Small parts in pilot valve are sensitive to contaminant particles.

Soft goods typically installed in pilot valves cannot withstand higher temperature fluids.

PRODUCT

Contact Us

Contact: Dandy

Email: australiadaume@outlook.com

Add: 54 Orchard St, Glen Waverley VIC 3150