Sleeve control valve

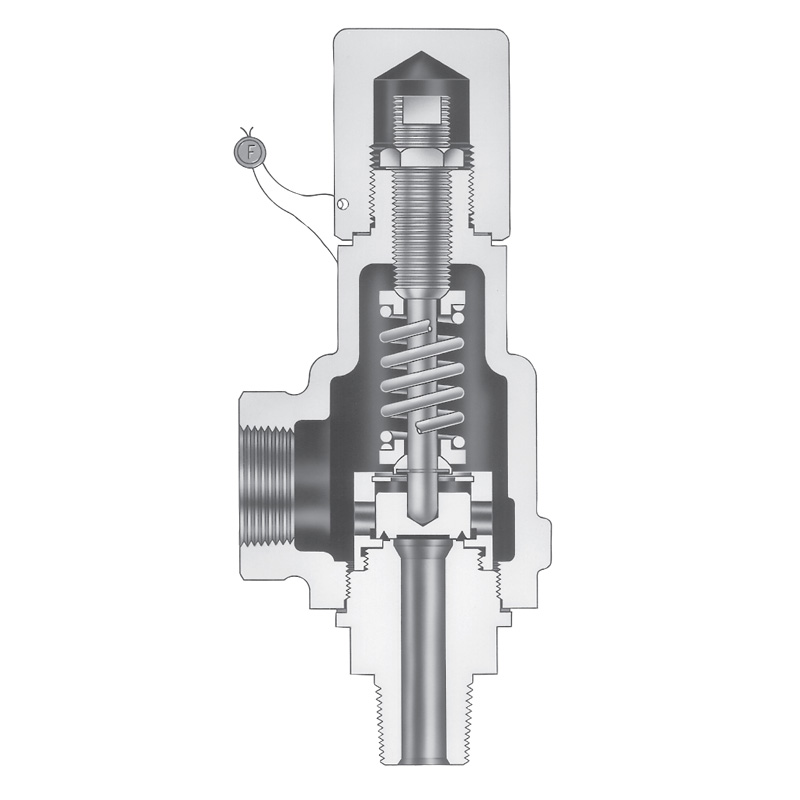

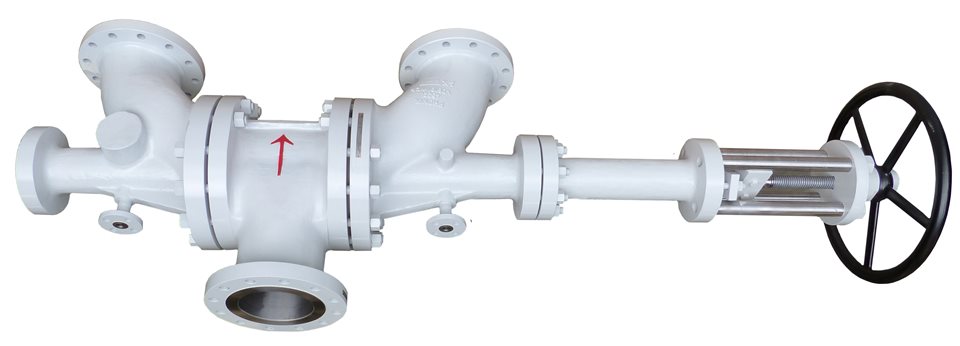

The single seat (sleeve) control valve is composed of pneumatic multi spring diaphragm actuator and low flow resistance straight through single seat valve (sleeve valve). The valve body of single seat valve is straight through the single seat cover and the valve core is of plunger type structure. Compared with the ordinary single seat valve, it has the characteristics of small volume, light weight and large flow rate. It is suitable for large flow and strict leakage requirements, and is widely used in low noise, low noise, high flow rate, etc In the industrial process automatic control system with large pressure difference.

Valve type straight through single seat cast spherical valve

Nominal diameter 25,32,40,50,65,80,100,125,150,200,300,500mm

Nominal pressure pn1.6,4.0,6.4mpa

Flange standards jb79-59, jb78-59, etc

Materials: cast steel (zg230-450), cast stainless steel (zg1cr18ni9ti, zg1cr18ni12mo2ti), etc

Upper valve cover common type upper valve cover: - 40 ~ + 230 ℃ radiator type upper valve cover + 230 ~ + 450 ℃

Gland type bolt compression type

Packing: V-type polytetrafluoroethylene packing, asbestos packing with impregnated polytetrafluoroethylene, asbestos braided packing and graphite packing

Valve assembly

Spool type single seat plunger type spool

Flow characteristics equal percentage characteristics and linear characteristics

Materials: stainless steel (1Cr18Ni9Ti, 1cr18ni12mo2ti, 17-4PH, 9Cr18, 316L)

Stainless steel surfacing stellite alloy, titanium and corrosion resistant alloy

Executive Agency

Type pneumatic diaphragm actuator

Diaphragm material NBR with nylon cloth

The spring range is 20-100, 40-200, 80-240 kPa

Air supply pressure 140 ~ 400kPa

Signal interface M16 × 1.5 or ZG1 / 4

Ambient temperature - 25 ~ + 55 ℃

Valve action type: air to close or air to open

Accessories positioner, air filter pressure reducer, position keeping valve, travel switch, valve position transmitter, hand wheel mechanism, etc

PRODUCT

Contact Us

Contact: Dandy

Email: australiadaume@outlook.com

Add: 54 Orchard St, Glen Waverley VIC 3150