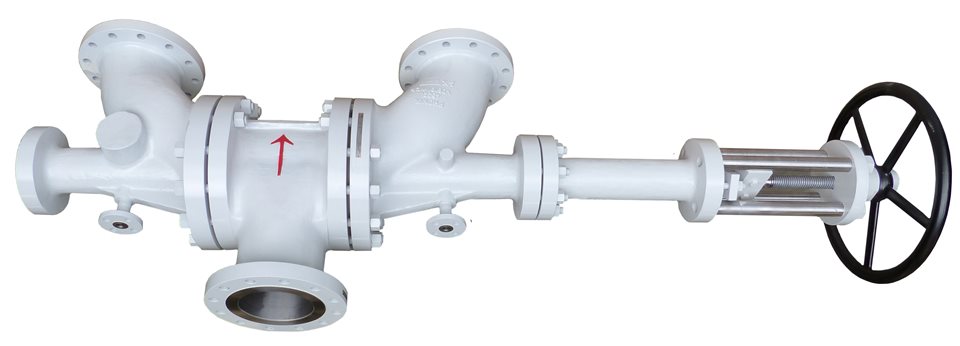

Triple eccentric butterfly valve

Product features:

1. Small volume, light weight, excellent cutting performance.

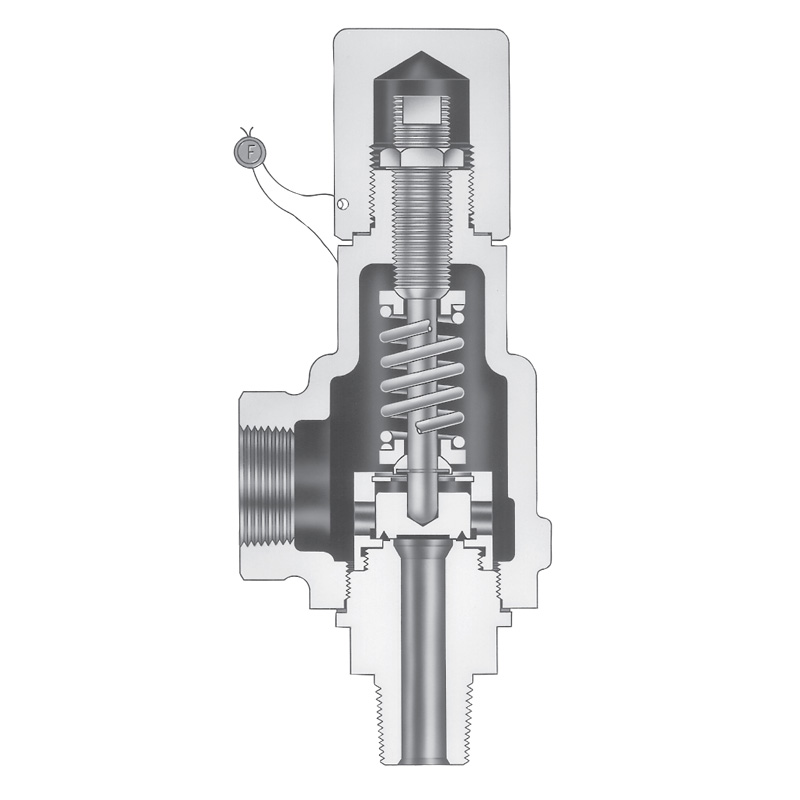

2. The sealing surface of butterfly plate is designed to be a conical surface with oblique section relative to the center of butterfly plate, so that there is a certain contact angle between the sealing surface of butterfly plate and the sealing surface of valve seat. The contact angle is uniform around its circumference, which is equal to a slender wedge, and the sealing line at the longitudinal position of the butterfly plate circumference presents a quasi elliptic curve, both of which play a sealing compensation role at the same time.

3. When the butterfly plate is closed, the force is uniform and the pressure bearing capacity is high; when the butterfly plate is opened, all points on the sealing surface of the butterfly plate can be separated from the sealing surface of the valve seat at the same time, and there is no jamming phenomenon, basically no friction, and the opening torque is very small. Therefore, the utility model has the advantages of low cost, good sealing performance and long service life.

4. Various sealing structures are available to ensure service life and reliability. Butterfly valve seal ring has integral soft seal (PTFE, c-tfe, g-tfe), hardened metal plate, integral + cemented carbide, suitable for various working conditions.

5. It can realize bidirectional sealing function, which can be adjusted and cut off.

6. The actuator has low friction force, high efficiency, high thrust and good safety.

7. The design of smart and combined actuator (manual mechanism) can ensure the random installation and flexible control in all directions.

8. Simple and eye-catching, reliable and integrated travel indication, combined installation of limit switch and solenoid valve, no external pipeline and less leakage points.

9. A variety of actuator forms can be selected to meet the requirements of different users.

10. Assembly and maintenance is convenient, with superior performance price ratio.

PRODUCT

Contact Us

Contact: Dandy

Email: australiadaume@outlook.com

Add: 54 Orchard St, Glen Waverley VIC 3150