Temperature and pressure reducing device

According to whether the temperature and pressure reduction are integrated, they can be divided into the following two categories

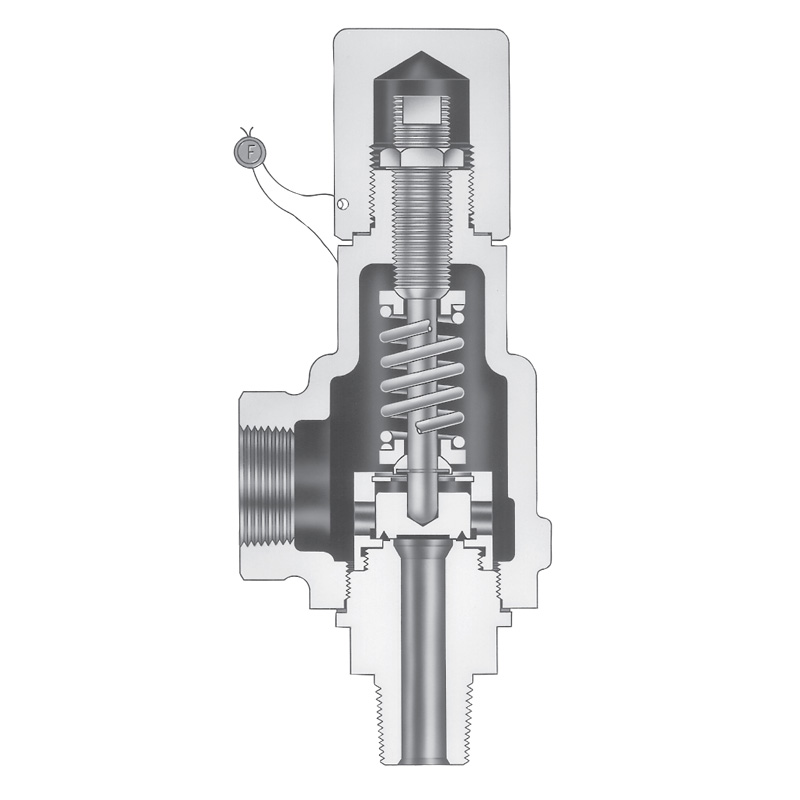

1) Integrated temperature and pressure reducer, temperature and pressure reduction in the same temperature and pressure reducing valve

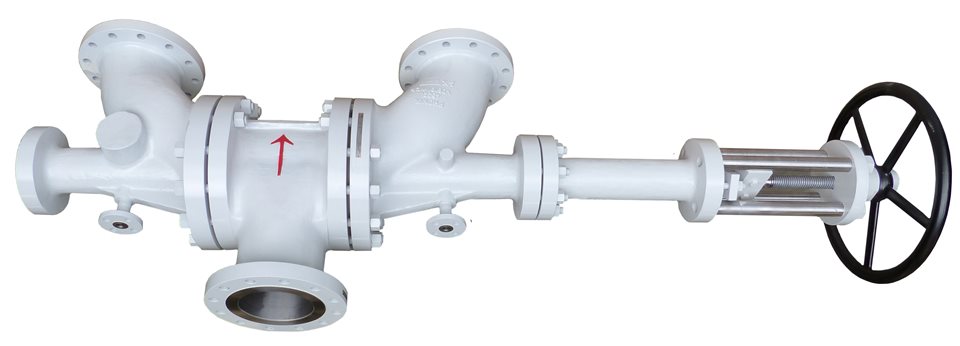

2) The split type temperature and pressure reducer has the advantages of high control precision, stable operation, sensitive adjustment, and can effectively eliminate the influence of static difference, etc

1. Cogeneration heating network central heating.

2. Power plant or industrial boiler and thermal power plant.

3. Steam inlet of heat exchange station or heat exchanger.

4. Steam power inlet of lithium bromide refrigeration unit.

5. Power and heat consumption of petrochemical, textile, papermaking, pharmaceutical, food and other production process equipment.

The temperature and pressure reducer is composed of control system, pressure reducing system, water spray desuperheating system and safety protection system. Its characteristics are as follows:

1. Control system: the main controller adopts high-precision multi-functional digital controller, with powerful functional components, good human-machine interface and fast and accurate PID control loop, realizing intelligent unattended, flexible parameter setting, and function expansion according to user requirements.

2. Pressure reducing device: the steam decompression process is realized by throttling the pressure reducing valve and orifice plate, and the decompression stage is determined by the difference of steam pressure after the decompression of new steam. The pressure regulation of the pressure reducing valve is completed by the electric actuator of the large actuator, with stable operation and long service life. According to the set value requirements of the secondary steam, no matter how the primary steam pressure fluctuates, it can keep the secondary steam pressure stable.

3. Desuperheating device: the desuperheating water atomization device specially designed by aero dynamics technology uses fluid self power to reduce equipment power consumption. The desuperheating water is crushed into mist like water droplets, mixed with steam and evaporated rapidly, so as to reduce the steam temperature.

PRODUCT

Contact Us

Contact: Dandy

Email: australiadaume@outlook.com

Add: 54 Orchard St, Glen Waverley VIC 3150