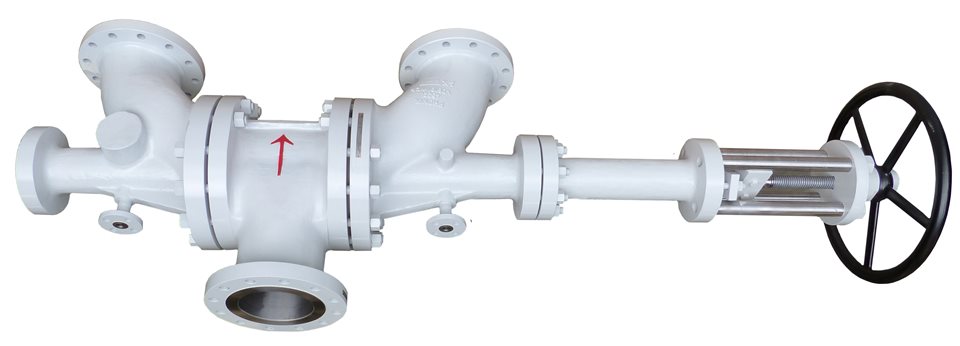

Desulfurization butterfly valve

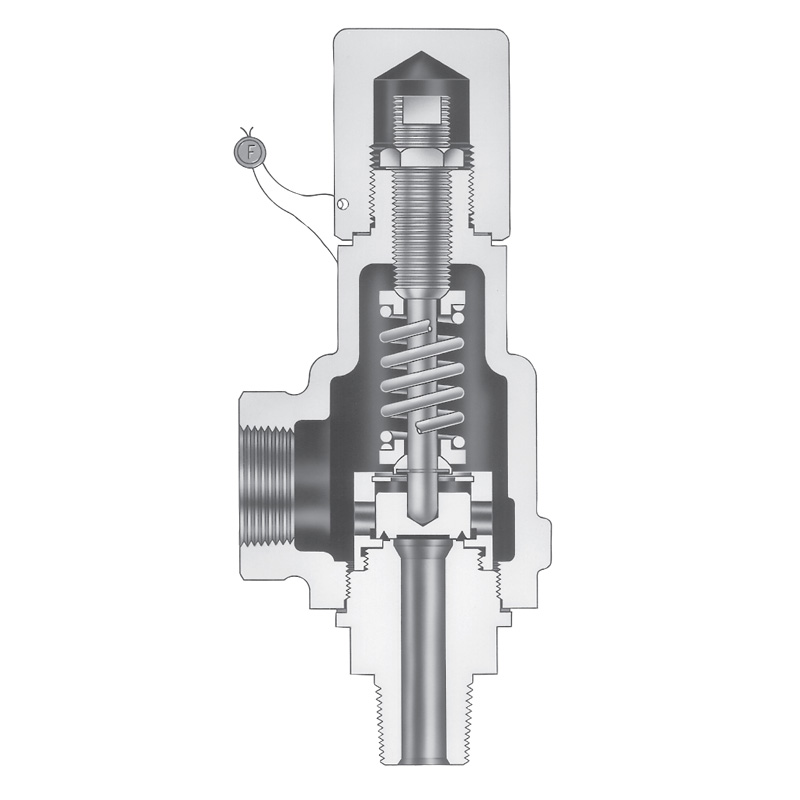

According to the physical and chemical characteristics of different media, the corresponding butterfly plate and valve seat materials can be selected to achieve different characteristics of high temperature resistance, low temperature resistance, corrosion resistance, light resistance and aging resistance.

High temperature electrostatic spraying epoxy resin powder coating can be used on the inner and outer surface of nodular cast iron butterfly plate. The coating has high corrosion resistance and high bonding strength with nodular cast iron matrix. The coating degree is 0.2-0.5mm

The valve plate of butterfly valve is made of high-performance alloy dual phase steel 2507, 1.4529 and other super corrosion-resistant alloys, which can effectively resist the corrosion and wear of slurry, and can be used in higher ambient temperature.

Main parts materials of desulfurization butterfly valve

Valve body gray iron, ductile iron, carbon steel

Butterfly plate carbon steel coated rubber, carbon steel coated fluoroplastic, stainless steel duplex stainless steel plate 1.4529, C276

Valve seat natural rubber, EPDM, rubber

Stem stainless steel, 2Cr13, 304

Last:Denitration ammonia injection regulating valve

Next:no more

PRODUCT

Contact Us

Contact: Dandy

Email: australiadaume@outlook.com

Add: 54 Orchard St, Glen Waverley VIC 3150