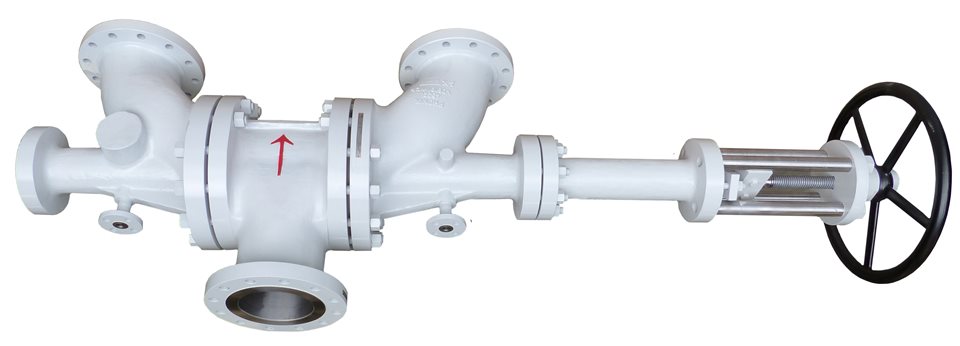

Three way regulating valve at inlet and outlet of high pressure heater

High pressure heater series three-way valve is specially designed for high-pressure heater operation and train switching. The system layout can be the combination of inlet and outlet tee, or the combination of inlet three-way valve, outlet angle type or gate valve, depending on the user's on-site pipeline layout or pipeline design. According to the American ANSI standard, the working temperature is up to 300 ℃, the pressure level can reach cl2500, and the valve body size ranges from DN350 to dn550din (14 ″ ~ 22 ″ ANSI). The control mode can be hydraulic and electric.

The feed water bypass system is always in standby state. If the water level in the heater shell rises due to the fault of the heater, the feed water bypass valve will act immediately. By monitoring the water level in the heater shell, the feed water bypass system can be automatically controlled. When the water level becomes too high, the feed water bypass valve opens to bypass the heater and isolate the heater.

High pressure three way heater typical inlet

The spherical valve body is specially designed for peak load operation and frequent start-up. It avoids the concentration of materials and sudden change of wall thickness. It is beneficial to maintain the overall concentricity of the valve, improve the sealing performance and reduce the requirement of operation control force.

The valve body material is 15NiCuMoNb5 (WB36), which is the same as that of high pressure heater water supply pipeline. It can be directly welded without adding transition section.

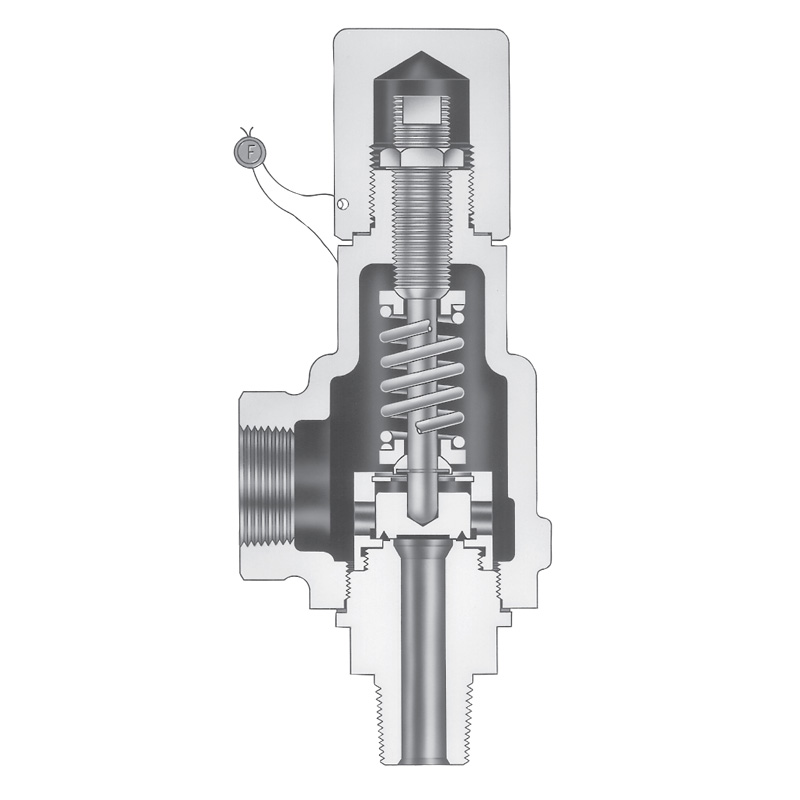

The axial position of the upper seal seat is fixed to ensure that the travel is fixed; and it is a detachable structure, which is convenient for maintenance.

The sealing surface adopts cobalt base alloy surfacing, which has long service life, wear resistance, scratch resistance and tight sealing.

The valve rod is made of high-strength stainless steel, and the sliding parts in contact with the valve stem are treated with surface hardening treatment to form distinct hardness difference and prevent the matching parts from seizing each other.

Butterfly spring is used at the head of valve stem to ensure sufficient preload to prevent valve from jamming when opening and closing.

PRODUCT

Contact Us

Contact: Dandy

Email: australiadaume@outlook.com

Add: 54 Orchard St, Glen Waverley VIC 3150