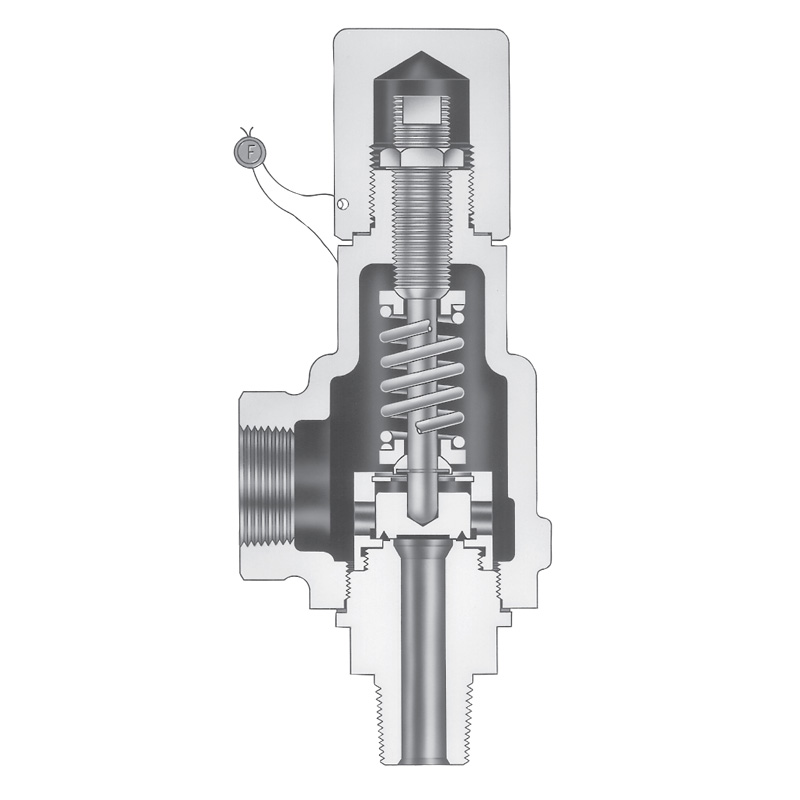

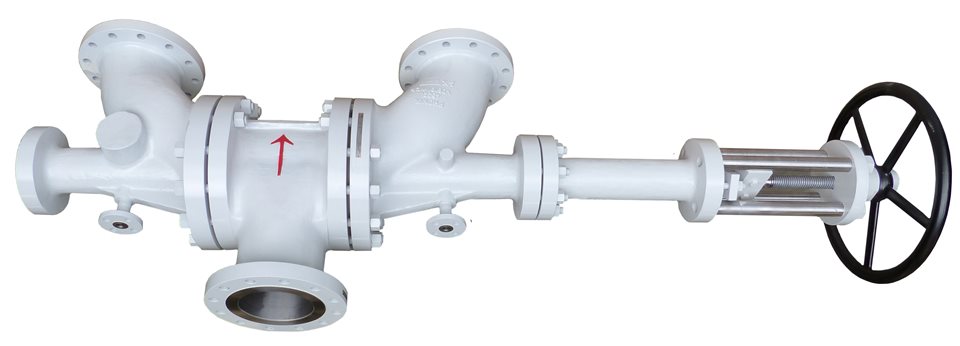

Mechanical pump protection valve

When the flow rate is less than the set value, the liquid will pass through the opening on the valve seat and through the valve stem, which is also the pressure reducing regulating channel of the bypass spool for bypass circulation. When the outlet flow rate is greater than the set flow rate, the fluid enters the main pipe and gradually closes the bypass for normal flow. The opening and closing of bypass and main flow is only related to outlet flow. When there is reverse flow at the outlet of the valve, the reverse action of the valve core becomes the working process of the check valve.

Features:

The investment cost of equipment is reduced

There is no need for thermal flash to occur

No additional power and control signals are required

The design is simple and the installation is convenient

Energy saving

Compact structure, automatic operation, no actuator required

Simple maintenance

Fail safe open bypass

The speed control system is also applicable

Structural parameters:

1. Nominal diameter: DN50 ~ 400

2. Project pressure: PN10 ~ 250

3. Bypass size: 1 / 2DN (standard); or special

4. Recommended flow rate: 4 ~ 6 m / s, maximum 8 m / S

5. Connection mode: flange connection (ANSI or DIN)

6. Cast carbon steel, forged carbon steel, cast chromium nickel molybdenum beryllium stainless steel, forged chromium nickel molybdenum beryllium stainless steel

7. Internal material: Forged chromium stainless steel forged chromium nickel stainless steel forged chromium molybdenum stainless steel

Application range:

Boiler feed water, cooling water and condensate equipment of nuclear power plant; petroleum, chemical industry and refrigeration equipment; drinking water supply and waste water treatment system; fire fighting system and water injection pump of offshore platform; hot rolling descaling and cooling system of iron and steel plant; boiler water pump and fire fighting system of loading and ship; pulp collapse and snow making equipment of paper mill.

PRODUCT

Contact Us

Contact: Dandy

Email: australiadaume@outlook.com

Add: 54 Orchard St, Glen Waverley VIC 3150