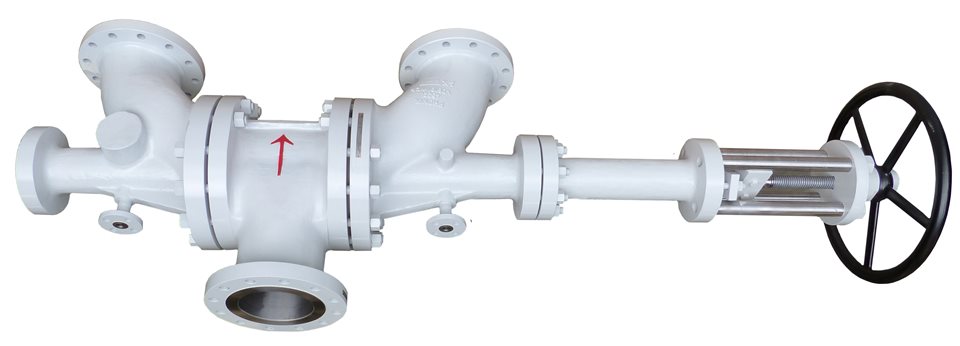

Y-type pneumatic drain valve

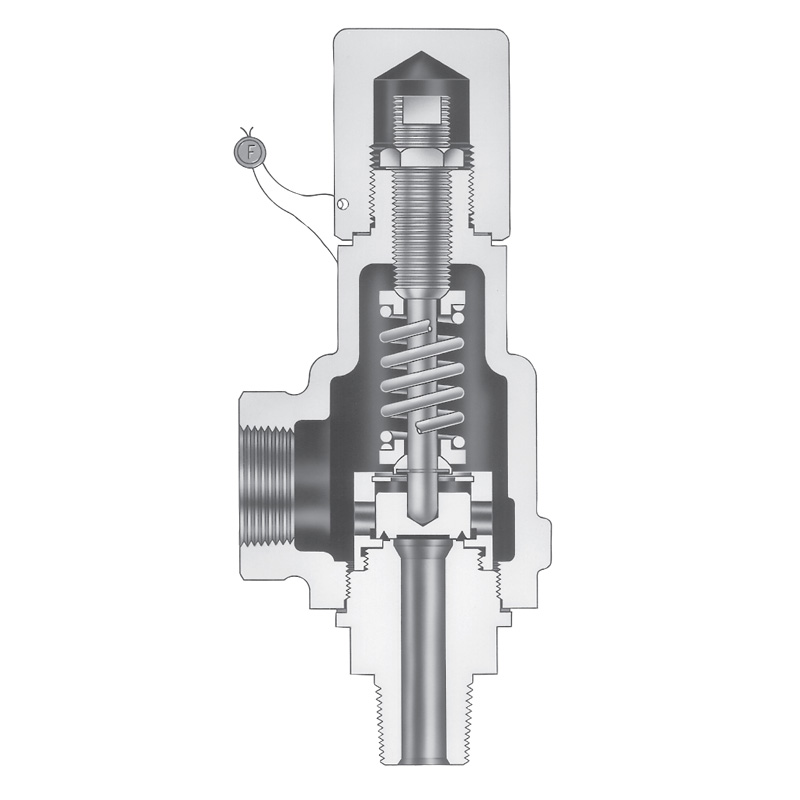

The upper part of Y-type pneumatic drain valve is composed of valve cover and packing box, which is convenient for quick disassembly and in-situ maintenance. The structure of the inclined stem and the optimum design of the flow passage shape make the medium close to the straight line. The valve has the best CV value and produces lower pressure drop than other types of valves. The valve body is overlaid with cemented carbide sealing surface by special technology (the sealing surface is hardened as a whole), so the structure is more compact. The conical sealing surface design can seal with small axial force, which can provide reliable sealing and long service life. The valve disc guided by the middle chamber of the valve body has two guide rings, the top and bottom of the valve disc guide at the same time, forming a piston type valve disc guided in the middle cavity of the valve body throughout the whole process. It can eliminate the phenomenon of jamming, surface scratch, valve stem bending and valve flap vibration caused by various improper forces. The guide ring at the bottom of the valve disc passes 90% of the fluid in a straight line, effectively eliminating all side impact induced adverse reactions. These features make the valve suitable for rapid steam "drain" and "drain" systems in power plants.

The sealing surface of valve disc is overlaid with cemented carbide, which has excellent mechanical properties, wear resistance, erosion resistance, and can maintain the long service life of the valve.

The valve stem packing adopts special packing, which can play the best leak proof effect, and it is durable and easy to disassemble and assemble. The packing box and valve body are sealed with 316 high mesh flexible graphite gasket, which is assembled with predetermined torque, which is safe and reliable and can prevent leakage.

Pneumatic device is used as the actuator to control the valve accurately, safely and effectively

The stuffing box adopts special structure design to ensure enough strength and good thermal characteristics.

The groove size of butt welding shall be in accordance with ansib16.25

The weld size is as per ansib16.34

Socket welding diameter range: 1 / 2 "~ 2-1 / 2"

Diameter range of butt welding: 1 / 2 "~ 4"

PRODUCT

Contact Us

Contact: Dandy

Email: australiadaume@outlook.com

Add: 54 Orchard St, Glen Waverley VIC 3150